What is an autoclave and how does it sterilize bottles?

In line with our values to protect the environment through stewardship and action, our lab reuses microbiological sample bottles from our most frequent testing program! In fact this procedure reduces our plastic waste by over 2,000 bottles a year! Staff thoroughly cleans bottles with soap and water and autoclaves them for sterilization. Autoclaving prepares the bottle for re-use by killing any bacteria that may be in the bottle.

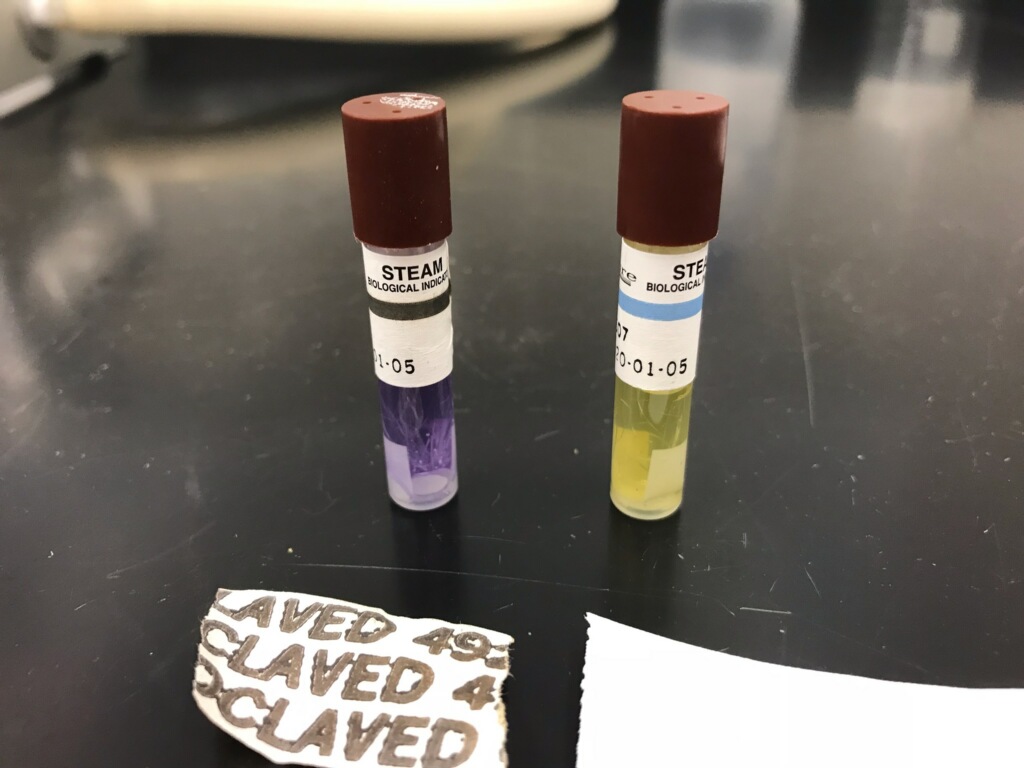

In order to ensure the autoclave is operating properly, we run a quality control (QC) called BTSure (see picture). Another is using autoclave tape, which changes color to indicate that the autoclave reached sterilizing temperature. Each vial contains microorganisms. The vials start off purple in color with a blue line on the label. If the vial turns yellow after 24 hours, this indicates bacterial growth. Once the BTSure is autoclaved and incubated for 24 hours, the vial should be purple. If not, this means there was bacterial growth and the QC failed. If the autoclave malfunctioning and not killing all bacteria, then this could impact our samples, skewing results and potentially making them invalid.

Picture captions:

This picture indicates a successful QC run in the autoclave! Left vial: When autoclaved, the line on the label turns black, indicating that it was exposed to stream under high pressure. The purple color indicates that no bacteria grew. The dark lettering on the tape also indicated that the autoclave reached the proper temperature. Right vial: This vial is called a control. This means it was not autoclaved. The vial is yellow indicating that bacteria grew. The white piece of tape is what it looks like before being autoclaved or what it would look like if the autoclave did not reach the intended temperature.